To Purge or Not To Purge (Mar. 20, 2018)

The Importance of Purging Compounds

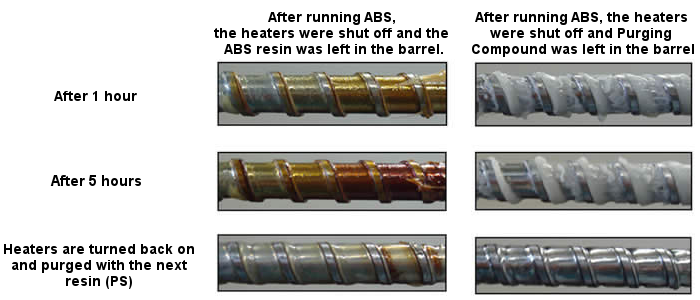

Most thermoplastic & engineered resins are likely to degrade and cause product contamination when left in the barrel, even for a short period of time.

When a production line is shut down there is simply no way to cool the resin quickly enough to avoid degradation (see picture above).

Methods such as flushing the machine with the next resin or flushing with regrind are time-consuming, material-wasting, and ineffective in removing color and carbon contamination.

A high-performance purging compound such as Cel-Span Purge is designed to not only facilitate color and material changeovers, but to thoroughly clean and maintain the machine as well.

Purging compound should be used to clean injection and extrusion units to ensure a smooth transition between materials, to ensure a line can be started up and shutdown quickly, to prevent contamination, and to prevent deposit formation.

Contact the plastic experts at JEG Inc. at 614-882-1295 to get the right Purging Compound for your needs.

Reply to this message or call us at 614-882-1295 for a consultation and free purge sample.